Frequently asked questions

Note: In these answers we will follow a few shorthand

conventions for describing user-interface procedures. Key combinations will be presented

like this: Ctrl+Alt+Delete, which means that you should press and hold

down the Control key, the Alt key, and the Delete key at the same time. Menu selections

will be presented like this: File->Open, which means that you should

open the File menu, and then make the Open selection.

- How do I enter an exact recipe?

- How can I find all glazes with 70% Silica?

- Where can I get more material analyses?

- Why should a Material Analysis be regarded with some scepticism?

- What is 'Loss on Ignition'?

- What is a 'Limit Formula'?

- Why does the analysis of a glaze need to be taken with a pinch of salt?

|

|

|

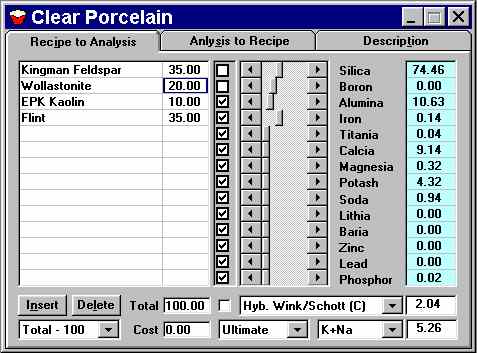

The materials in your recipe must be in the current database for you to enter your recipe. Open the Materials Window (Materials->List) and a new Recipe Window (Recipe->New).

Drag the materials you require in your glaze recipe to the recipe box on the left side of the recipe window. In the bottom far left drop down list select 'Fixed Entry'. Click on the material amount box, move the cursor to the position of the first digit of the amount you wish to type in and enter the amount. Repeat the process for all the materials in the recipe.

Once all the materials and their amounts have been entered select 'Total - 100" instead of 'Fixed entry'. All the material amounts will be converted to a percentage of the total recipe weight.

Click on the

![]() button to open the material search window. Move the

button to open the material search window. Move the

![]() left slider so that the corresponding

amount is 70% and then move the

left slider so that the corresponding

amount is 70% and then move the

![]() right hand slider down to 71.

Now click on 'List' and the Recipe List Window will open with all glazes containing

between 70% and 71% Silica.

right hand slider down to 71.

Now click on 'List' and the Recipe List Window will open with all glazes containing

between 70% and 71% Silica.

In the future databases will be made available for various Raw Materials but in the meantime try Digital Fire

Mining Companies analyse the raw materials they supply and will often blend to achieve consistency. Your pottery supplier should be able to give you the analysis of any material they supply. You should bear in mind that lines may be discontinued if deposits run out. In such cases a substitute will have to be found.

You may well come across analyses of wood ashes. Do not presume that, for example, all apple ash has the same analysis. A tree's chemical analysis will depend on its environment let alone its species.

Raw materials are usually supplied with a specific water content (usually 5% to reduce dust). This will not need to be taken into account when formulating glazes if all the raw materials have the same water content. Due to evaporation the water content of a material will vary and this will in turn have an effect on the percentage of that material in a glaze recipe.

As the name implies, 'Loss on Ignition' is the weight of the raw material that is burnt off during a firing of approx. 1050oC. It does not include volatilized gases.

Attempts have been made to give limits to the oxide percentages of certain types of glazes for different maturing temperatures but they should only be taken as a rough guide. To get the required result it would be wise to start with a known glaze (or several) and do a series of tests using, for instance, a triaxial blend. It will usually be found that similar effects can be achieved outside the limits set through the use of eutectics and the variation of the glaze firing cycle. The key is to experiment with a minimum of variants. Try to keep the firing and raw materials the same and only change the proportions of the materials in the recipe. The Glaze Calculator will help users understand the relationship of the various oxides in a glaze and the rolls they have to play (right clicking on an oxide will bring up a description of that oxide and the common materials that can be used to supply it).

There are many variables, besides the chemical analysis of a glaze, that effect its fired result. The particle size of the raw materials and the firing cycle can drastically change the appearance of a glaze. The latter is particularly relevant with regards to glazes fired in a reduction atmosphere.